Are you wanting to expand your product offering with a high profit consumable item? If so, labels are what you’re looking for! Follow the 5 Key Questions below to get started on your label journey. Each answer is a simple step into winning repeating business.

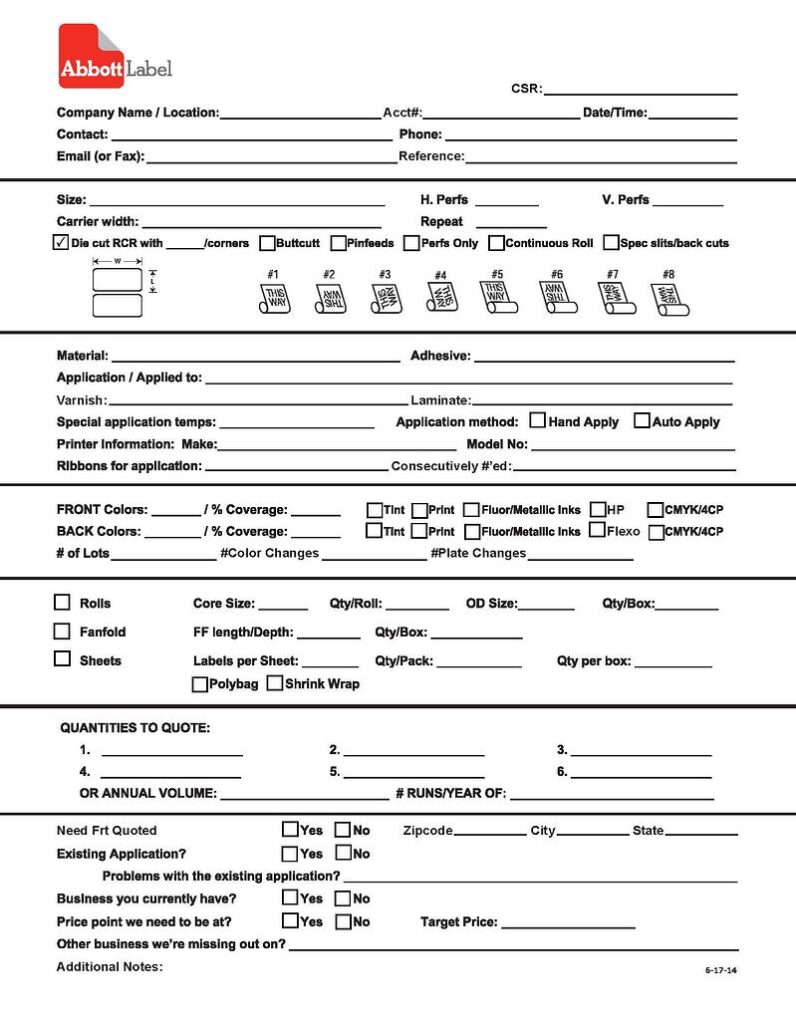

Below is an example of the quote sheet your Abbott Label rep fills out for each custom quote opportunity.

The 5 key questions to ask, covered below, will help us get you the quote you need faster.

1. What is the size of the label (Width x Length)?: In the label industry we measure a finished label width x length. We want to know the size so we can search our die inventory to see if we already have a tool that will work for the job. If not, we send the measurements to our DIE tool manufacture to build a new custom cutting die for your order.

2. What is the material and / or application?: If your customer has a specific material spec they use it is not a problem. Simply forward the spec to your Abbott Label representative when requesting a quote.

If you do not know the material, no problem! Just let your Abbott Label representative know what the label application is. From there we can take our 40 years of experience to suggest the perfect material / adhesive.

3. Is it printed? If yes, how so?: If Abbott Label is printing the label with either flexographic or digital printing technology; please let your Abbott Label representative know how many colors will be printed.

If you’re not sure, get artwork or a sample and forward to your representative.

BLANK LABELS CAN BE PRINTED! Some blank labels will be printed by your customer with a Thermal Transfer, Direct Thermal, Laser or InkJet printer. If you or your customer are not sure which method – let your rep know the make and model of the printer they are using.

4. Rolls – Fan Fold – Sheets?: Labels can come in all sorts of shapes and sizes. However the dispensing mode they are finished to comes down to three options:

Rolls: Labels will be rolled on a paper core. Industry standard is 3″ core diameter with an 8″ outside diameter. A secondary standard for smaller printers / dispensers is a 1″core with an 4″ outside diameter.

NOT SURE? Just find the printer’s / applicator’s make and model number. With that information your Abbott representative can suggest the correct size to maximize load capacity.

Fan-Fold: Accordion style folding at the perforation – stacked in a box. Fan-fold items can be finished with multiple rows of labels across. Most commonly used with thermal transfer, direct thermal or dot matrix printing.

Sheets: Single cut out sheets – may have internal cuts on a sheet. Stacked between chip-board inside of a poly-bag for curl protection. Then placed in a box and labeled. This is most commonly seen for return label packing slips and other laser printed items.

5. How many labels will they order at a time?: How many labels will they be ordering at a time? Abbott Label does not have a minimum but can offer discounts with larger volume orders. With our excellent service and quick turn times, Abbott Label is a great partner for Just In Time programs!